Category : Electric control valve

Product Name: Fluorine Anti-corrosive Electric Control valve

Product introduction:

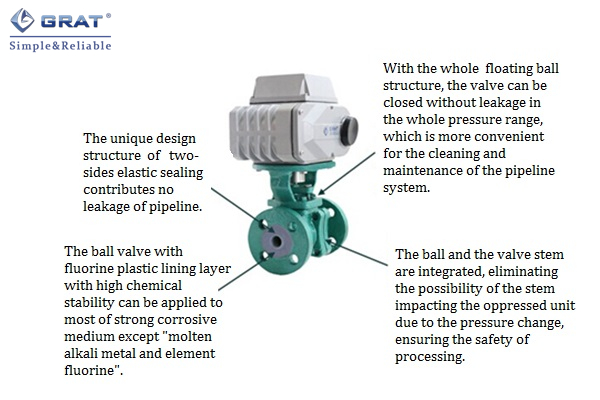

Fluorine Anti-corrosive Electric Control valve is designed to switch and cut off various strong corrosive medium which is widely applied in petroleum chemical pesticide dye acid alkali and so on and which is the best choice for anti-corrosion equipment at present.

This valve which adopts polytetrafluoroethylene (FEP) as anti-corrosion lining material has very superior anti-corrosion and abrasion resistance. The unique structure for lip type elastic seal parts well extends the service life of the products.

It configured with the intelligent actuator which can make the precise control receives the 4-20 MA or 1-5 VDC signal from high precision electric actuators and indicates the angle of direct instruction and feedback.

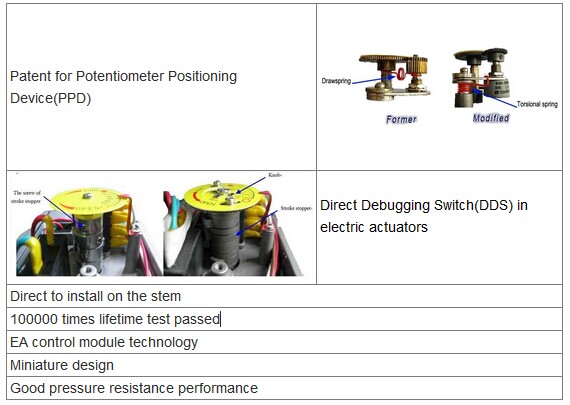

The advantage of electric actuator

| Power supply | AC220V/AC380V/DC24V |

| Valve size | DN15-350 |

| Medium Temp | -15℃ ~ 150℃ (No congelation) |

| Operating pressure | PN1.0~2.5(MPa) |

| Action mode | Switch to cut off,0-90° gyration |

| Action time | 4-30S |

| Body connections | Flange |

| Body material |

WCB、ZG1CrM0、ZG1Cr18Ni9Ti SS304、SS316 |

| Seal material | polytetrafluoroethylene (FEP) |

| Actuator material | Casting aluminum alloy |

| Applicable medium | Acid alkali salt chlorine gas steam source water mine pulp and paper pulp aqua regia oxidant corrosive chemical liquid |

| Part name | Body | Bonnet | Stuffing box | Gland ring | Seat | Packing | Spanner |

| Material trademark |

WCB ZG1CrM0 ZG 1Cr18Ni9Ti |

WCB ZG1CrM0 ZG 1Cr18Ni9Ti |

WCB 40Cr ZG 1Cr18Ni9Ti |

WCB

ZG1CrM0 ZG 1Cr18Ni9Ti |

FEP | FEP |

WCB |

| Medium state | Medium Temp | Medium pressure | Medium characteristics | Medium concentration | Medium name |

| Liquid | -80℃~+160℃ | 0~20kg/cm2 | Strong corrosion high scour sharpen | unlimited |

Acid alkali salt chlorine steam source water mine pulp paper pulpaqua regiaoxidantreducing agen |

| Gas | -80℃~+160℃ | 0~20kg/cm2 | Strong corrosion high scour sharpen | unlimited | |

| Mixture of liquid and solid | -80℃~+160℃ | 0~20kg/cm2 | Strong corrosion high scour sharpen | <60% |

|

Body ratings (PN) |

Strength (MPa) | Seal (MPa) | lining insulation test voltage | ||||

| 1.0 | 1.6 | 2.5 | 1.0 | 1.6 | 2.5 | ||

| Test pressure value | 1.5 | 1.82 | 2.6 | 1.1 | 1.7 | 2.5 | 20KV |

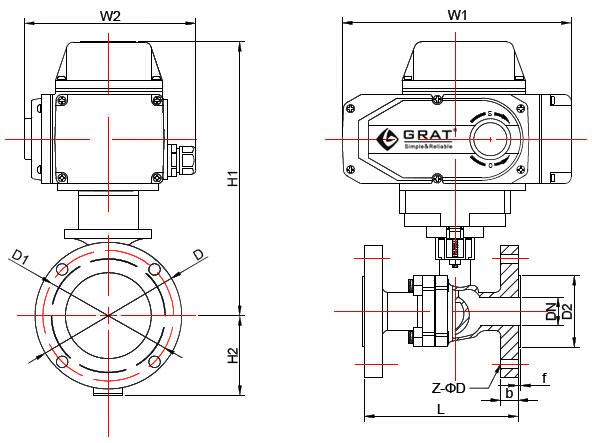

Figure and size

Design standard:HG/T 20592

Flange standard:HG/T20592 Unit:(mm)

|

Inside nominal diameter |

Diameter (Inch) |

L |

D |

D1 |

D2 |

b |

f |

Z-ΦD |

H1 |

H2 |

W1 |

W2 |

|

15 |

1/2" |

130 |

95 |

65 |

45 |

16 |

2.5 |

4-14 |

216 |

47.5 |

196 |

145 |

|

20 |

3/4" |

140 |

105 |

75 |

55 |

18 |

2.5 |

4-14 |

231 |

52.5 |

196 |

145 |

|

25 |

1" |

150 |

115 |

85 |

65 |

19 |

3 |

4-14 |

236 |

57.5 |

196 |

145 |

|

32 |

1.2" |

165 |

140 |

100 |

78 |

19 |

3 |

4-18 |

256 |

70 |

196 |

145 |

|

40 |

1.5" |

180 |

150 |

110 |

85 |

19 |

3.5 |

4-18 |

261 |

75 |

196 |

145 |

|

50 |

2" |

200 |

165 |

125 |

100 |

19 |

3.5 |

4-18 |

271 |

82.5 |

196 |

145 |

|

65 |

2.5" |

220 |

185 |

145 |

120 |

19 |

3.5 |

4-18 |

303 |

92.5 |

255 |

182 |

|

80 |

3" |

260 |

200 |

160 |

135 |

20 |

3.5 |

8-18 |

358 |

100 |

255 |

182 |

|

100 |

4" |

280 |

220 |

180 |

155 |

21 |

4 |

8-18 |

383 |

110 |

255 |

182 |

|

125 |

5" |

320 |

250 |

210 |

185 |

23 |

4 |

8-18 |

403 |

125 |

255 |

182 |

|

150 |

6" |

360 |

285 |

240 |

210 |

25 |

4 |

8-22 |

433 |

142.5 |

255 |

182 |

|

200 |

8" |

400 |

340 |

295 |

265 |

25 |

4 |

12-22 |

476 |

170 |

255 |

182 |

|

250 |

10" |

450 |

405 |

355 |

320 |

26 |

4 |

12-26 |

555 |

225 |

354 |

273 |

|

300 |

12" |

500 |

460 |

410 |

375 |

28 |

4 |

12-26 |

- |

250 |

354 |

273 |

|

350 |

14" |

610 |

520 |

470 |

435 |

29 |

5 |

16-26 |

- |

305 |

354 |

273 |

Standard of products

| Design and manufacturing standards | GB12237-89 AP16D |

| Flange standards | JB79 GB9113 ANSI B16.5 JIS B2212 |

| Structure length standards | GB1221-89 |

| Inspection standards |

JB/T 9092 API598 |

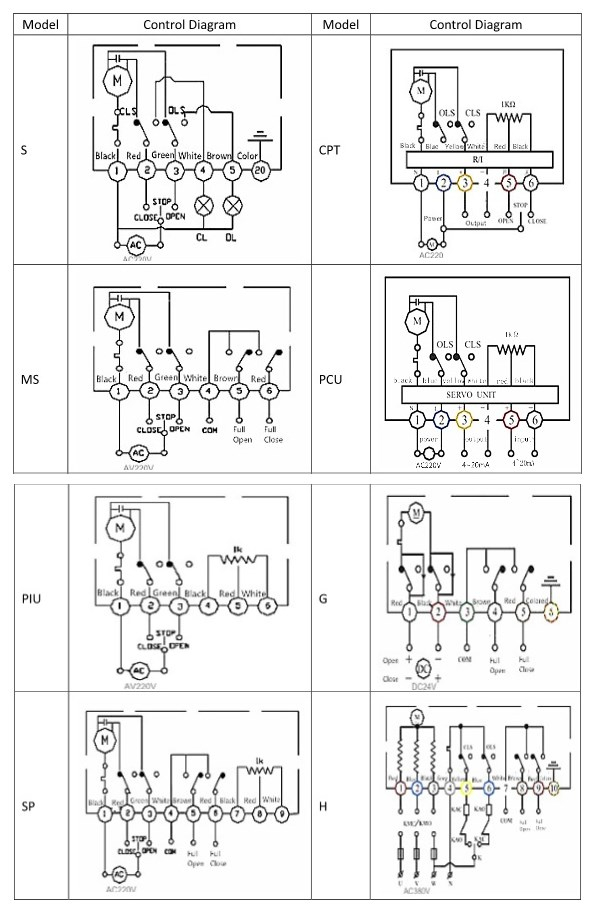

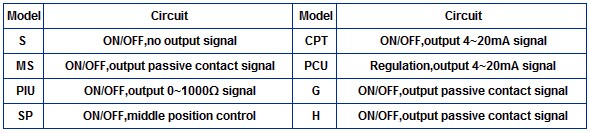

Control diagram

Leading manufacturer of industrial automation equipment