Category: Electric ball valve

Product Name: Explosion-proof Flanged Electric Ball Valve

Product introduction:

Flange type explosion-proof electric ball valve is the rotation Angle of 0-90° ball valve with excellent sealing performance circulation capacity flow resistance coefficient is small simple structure convenient maintenance long service life valve channel and connection pipe diameter and into a diameter the medium can almost no loss of flow.

The control mode can be switch on-off type or regulation type. Its usually used in the occasions with strict sealing requirements in addition to controlling gas liquid and steam medium it is also suitable for controlling sewage and medium containing fibrous impurities widely used in petroleum chemical industry metallurgy light industry paper making power station refrigeration and other work fields.

The working principle of flanged electric ball valve is: the electric actuator drives the valve stem to drive a ball (or part of the ball) with a hole the ball rotates with the valve stem to realize the opening or closing of the valve;Electric ball valve can be fully closed and fully opened by rotating 0-90°. Compared with gate valve and globe valve of the same specification ball valve is small in size and light in weight which is convenient for pipe installation.

|

No leakage of two sides self-seal ball structure.

|

|

Special designed PTFE seal materialless the friction of the trim movement.

|

|

Excellent cuting ability of O type valve trim

|

Optional O type or Vtype valve trim

|

*All electrical and mechanical components are sealed in aluminum alloy shell with high instant explosion resistance pressure of 1.6MPa isolating the ignition source effectively.

*With "o "ring seal up to protection grade IP68 Each explosion-proof surface adopts circular clearance and CNC precision machining to achieve stable and reliable explosion-proof performance

*Powered by 1-phase 3-phase or DC power supplies

*Bus communication, Analog signal are available for your choice

*Permanently lubricated and maintenance free drive train

*Optional torque limiter/remote control

Explosion-proof grade:

TA: explosion-proof series products of explosion-proof level for Exd Ⅱ BT4

The Ex

D: Explosion-proof type: Explosion-proof

Ⅱ: Electrical equipment used in explosive gas environment except the coal mine of device

B: Explosion level: the size (width and clearance) of the explosion-proof surface in accordance with the explosion level

T4: Temperature group: the maximum temperature in surface is 135℃

In appendix B of GB3836.1-2000 the grade and temperature of combustible gas are listed in detail

[NOTED] the types and groups of explosive media around the place where the product is used must be consistent with those permitted by the product.Otherwise it can't play the explosion-proof effect in non-applicable environment

|

Power supply |

AC220V 50/60HZ |

|

Nominal diameter |

DN15-200 |

|

Medium temp. |

-20℃ ~ +350℃ (+200℃ special PPL) |

|

Nominal pressure |

PN16 PN25,PN40,PN64,PN100 |

|

Input signal |

4-20mADC1~5VDC |

|

Output signal |

4-20mADC |

|

Connection type |

Flange |

|

Body material |

A105、F304、F316、WCB、FZG1Cr18Ni9Ti、ZG1Cr18Ni12Mo2Ti、CF8、CF8M、CF3M |

|

Valve seat material |

PTFE(Nomal temp.)、PPL(Medium temp.)、STL Metal seal(High temp.) |

|

Leakage class |

Conformed to ANSIB16.104 -V class |

|

Seal type |

Soft seal 、PPL、Metal seal Ceramic |

|

Suited medium |

Water、Petroleum、Nitric acid、Acetic acid、Viscous fluid、Pulp、Oxidant |

|

Protection class |

IP68 |

|

Manufacture standard |

JB/T8692-1998 |

|

Length standard |

GB1221-89 |

|

Inspection standard |

JB/T 9092 API598 |

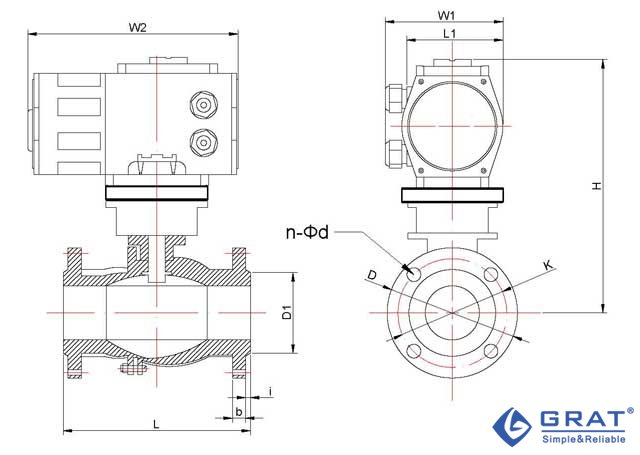

| Size | L | D | K | D1 | b | N/1 | i | H | W |

| 15 | 130 | 95 | 65 | 45 | 14 | 4-ø14 | 2 | 209 | 196 |

| 20 | 130 | 105 | 75 | 55 | 16 | 4-ø14 | 2 | 211 | 196 |

| 25 | 142 | 113 | 85 | 65 | 18 | 4-ø14 | 2 | 218.5 | 196 |

| 32 | 165 | 140 | 100 | 78 | 18 | 4-ø18 | 2 | 233 | 196 |

| 40 | 165 | 150 | 110 | 85 | 18 | 4-ø18 | 2 | 234 | 196 |

| 50 | 203 | 165 | 120 | 100 | 20 | 4-ø18 | 2 | 248 | 196 |

| 65 | 222 | 185 | 145 | 120 | 20 | 8-ø18 | 2 | 294 | 255 |

| 80 | 241 | 200 | 160 | 135 | 21 | 8-ø18 | 2 | 320 | 255 |

| 100 | 305 | 220 | 180 | 155 | 22 | 8-ø18 | 2 | 339 | 255 |

| 125 | 356 | 250 | 210 | 184 | 22 | 8-ø18 | 3 | 392 | 255 |

| 150 | 394 | 285 | 240 | 210 | 24 | 8-ø23 | 3 | 402 | 255 |

| 200 | 457 | 340 | 295 | 265 | 26 | 8-ø23 | 3 | 467 | 255 |

|

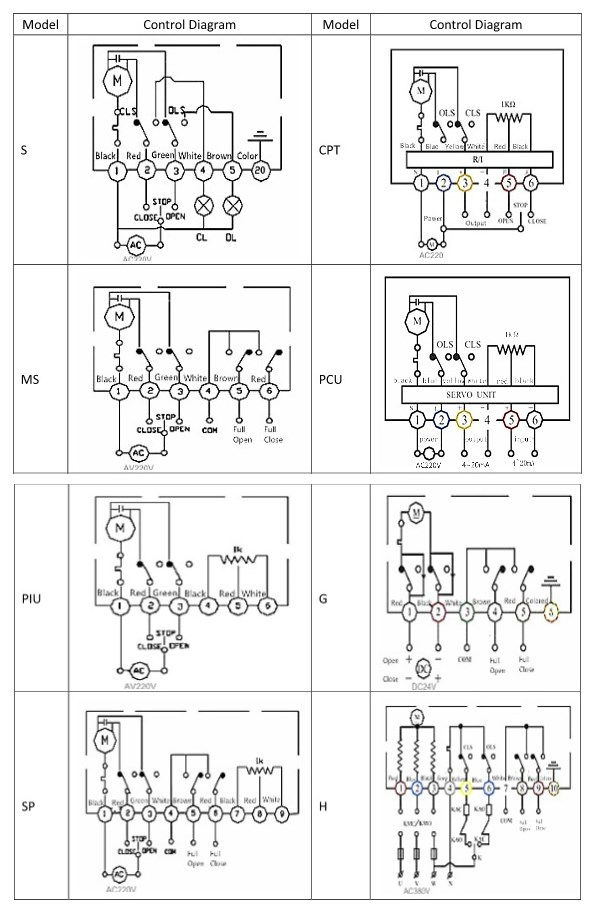

Model |

Circuit |

Model |

Circuit |

|

S |

ON/OFFno output signal |

CPT |

ON/OFFoutput 4~20mA signal |

|

MS |

ON/OFFoutput passive contact signal |

PCU |

Regulationoutput 4~20mA signal |

|

PIU |

ON/OFFoutput 0~1000Ω signal |

G |

ON/OFFoutput passive contact signal |

|

SP |

ON/OFFmiddle position control |

H |

ON/OFFoutput passive contact signal |

Leading manufacturer of industrial automation equipment