Category : Electric butterfly valve

Product Name : Explosion-proof Electric Butterfly Valve

Product introduction:

Explosion-proof Electric Butterfly Valve has the non-pin structure to effectively avoid the pin break off in a long- term operation as a modulation device to control and cut off the various industrial medium of water and oil to realize temperature pressure and flow control.

All electrical and mechanical components are sealed in aluminum alloy shell with high instant explosion resistance pressure of 1.6MPa isolating the ignition source effectively.

With "o "ring seal up to protection grade IP68 Each explosion-proof surface adopts circular clearance and CNC precision machining to achieve stable and reliable explosion-proof performance

This valve is suited to the pipeline and container of non corrosive gas liquid semi-liquid and solid powder and applied in the industrial fields of petroleum chemical food medicine textile papermaking power shipwater and drainage smelting energy and so on.

|

Nominal diameter |

DN40~DN800 |

|

|

Power supply |

AC220V,AC380V DC24V |

|

|

Fluid temp. |

-20~120℃ |

|

|

Ambient temp. |

-30℃-60℃ |

|

|

Nominal pressure |

0.1~2.5MPa |

|

|

Action time |

15S/30S/60S |

|

|

Suitable fluid |

Water Oil Gas Corrosive fluids. |

|

|

Control mode |

Regulation / Switch on-off |

|

|

Control signal |

4-20mA/0-5V~10V(Optional) |

|

|

Output signal |

4-20mA/0-5V~10V(Optional) |

|

|

Connection type |

Wafer |

|

|

Seal type |

Soft seal |

|

|

Test pressure |

Casing test |

1.76MPa |

|

Seal test |

2.4MPa |

|

|

Body material |

WCB、QT450-10、HT200、HT250、SUS304、SUS316 |

|

|

Disc material |

WCB、QT450-10、HT200、HT250、SUS304、SUS316 |

|

|

Stem material |

2Cr13 |

|

|

Seal ring material |

NBR EPDM PTFE PPL |

|

|

Seal material of stem |

NBR、HNBR |

|

|

Stuffing |

Soft graphite |

|

|

Protection class |

IP67 |

|

|

Manufacture standard |

GB/T 122387-89 |

|

|

Flange standard |

GB9113-2000、GB17241.6-1998 |

|

|

Length standard |

GB12221-89 |

|

|

Inspection standard |

GB/T 13927-92 |

|

|

Size |

mm | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1000 | 1200 |

| inch | 2" | 2.5" | 3" | 4" | 5" | 6" | 8" | 10" | 12" | 14" | 16" | 18" | 20" | 24" | 28" | 32" | 36" | 40" | 48" | |

|

CV data Full 90°Open |

135 | 220 | 302 | 600 | 1022 | 1579 | 3136 | 5340 | 8250 | 11917 | 16388 | 21705 | 27908 | 43116 | 49500 | 68250 | 86375 | 119750 |

187300 |

|

|

|

L |

D |

K |

N-φD |

H2 |

H1 |

W1 |

W2 |

|

40 |

33 |

72 |

--- |

--- |

48 |

210 |

138 |

76 |

|

50 |

42.6 |

92 |

125 |

4-Φ18 |

70 |

314 |

160 |

137 |

|

65 |

45.6 |

106 |

145 |

4-φ18 |

76 |

327 |

160 |

137 |

|

80 |

45.6 |

122 |

160 |

8-φ18 |

89 |

333 |

160 |

137 |

|

100 |

51.6 |

150 |

180 |

4-φ22 |

104 |

385 |

196 |

145 |

|

125 |

55.6 |

177 |

210 |

4-φ22 |

120 |

400 |

196 |

145 |

|

150 |

55.6 |

204 |

240 |

4-φ23 |

139 |

442 |

255 |

182 |

|

200 |

59.6 |

260 |

295 |

4-φ23 |

175 |

480 |

255 |

182 |

|

250 |

67.6 |

314 |

355 |

4-φ28 |

203 |

522 |

255 |

182 |

|

300 |

77.6 |

370 |

410 |

4-φ28 |

242 |

537 |

255 |

182 |

|

350 |

77 |

--- |

470 |

4-φ28 |

277.5 |

555 |

354 |

273 |

|

400 |

86.5 |

--- |

525 |

4-φ30 |

309 |

590 |

354 |

273 |

|

450 |

105.6 |

--- |

585 |

4-φ30 |

337 |

610 |

354 |

273 |

|

500 |

131.8 |

--- |

650 |

4-φ33 |

361 |

670 |

354 |

273 |

|

600 |

152 |

--- |

770 |

4-φ36 |

459 |

1110 |

520 |

470 |

|

700 |

163 |

--- |

840 |

4-φ36 |

527 |

1180 |

520 |

470 |

|

800 |

188 |

--- |

950 |

4-φ39 |

594 |

1220 |

520 |

470 |

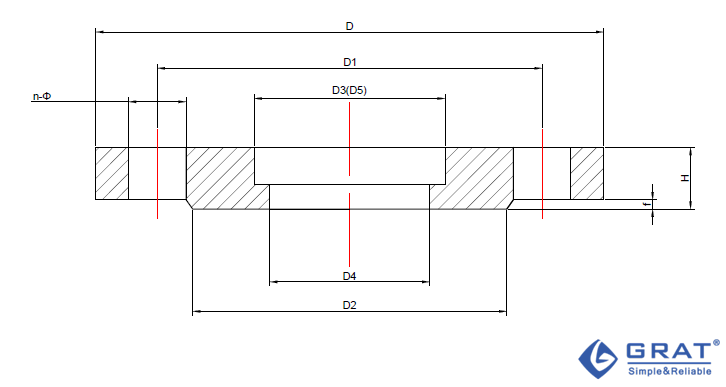

| Size (mm) | D | D1 | D2 | D3 | D4 | n-Φ | H | f | D5 |

| 50 | 165 | 125 | 59 | 52 | 52 | 4-Φ 18 | 20 | 3 | 62 |

| 65 | 185 | 145 | 122 | 75 | 67 | 4-Φ 18 | 20 | 3 | 78 |

| 80 | 200 | 160 | 133 | 91 | 82 | 8-Φ 18 | 20 | 3 | 91 |

| 100 | 220 | 180 | 158 | 110 | 102 | 8-Φ 18 | 22 | 3 | 116 |

| 125 | 250 | 210 | 184 | 135 | 127 | 8-Φ 18 | 22 | 3 | 142 |

| 150 | 285 | 240 | 212 | 161 | 152 | 8-Φ 22 | 24 | 3 | 170 |

| 200 | 340 | 295 | 268 | 221 | 208 | 12-Φ 22 | 26 | 3 | 221 |

| 250 | 405 | 355 | 320 | 275 | 255 | 12-Φ 26 | 29 | 3 | 275 |

| 300 | 460 | 410 | 370 | 327 | 308 | 12-Φ 26 | 32 | 4 | 326 |

| 350 | 520 | 470 | 430 | 379 | 355 | 16-Φ 26 | 34 | 4 | 358 |

| 400 | 580 | 525 | 482 | 429 | 405 | 16-Φ 30 | 36 | 4 | 409 |

| 450 | 640 | 585 | 532 | 481 | 455 | 20-Φ 30 | 38 | 4 | 460 |

| 500 | 715 | 650 | 585 | 532 | 505 | 20-Φ 33 | 42 | 4 | 511 |

| 600 | 840 | 770 | 685 | 633 | 605 | 20-Φ 36 | 44 | 5 | 613 |

Leading manufacturer of industrial automation equipment